Gwangju Institute of Science and Technology

Smart Diagnosis and Design Optimization Laboratory

> Research > Prognostics and Health Management

Prognostics and Health Management

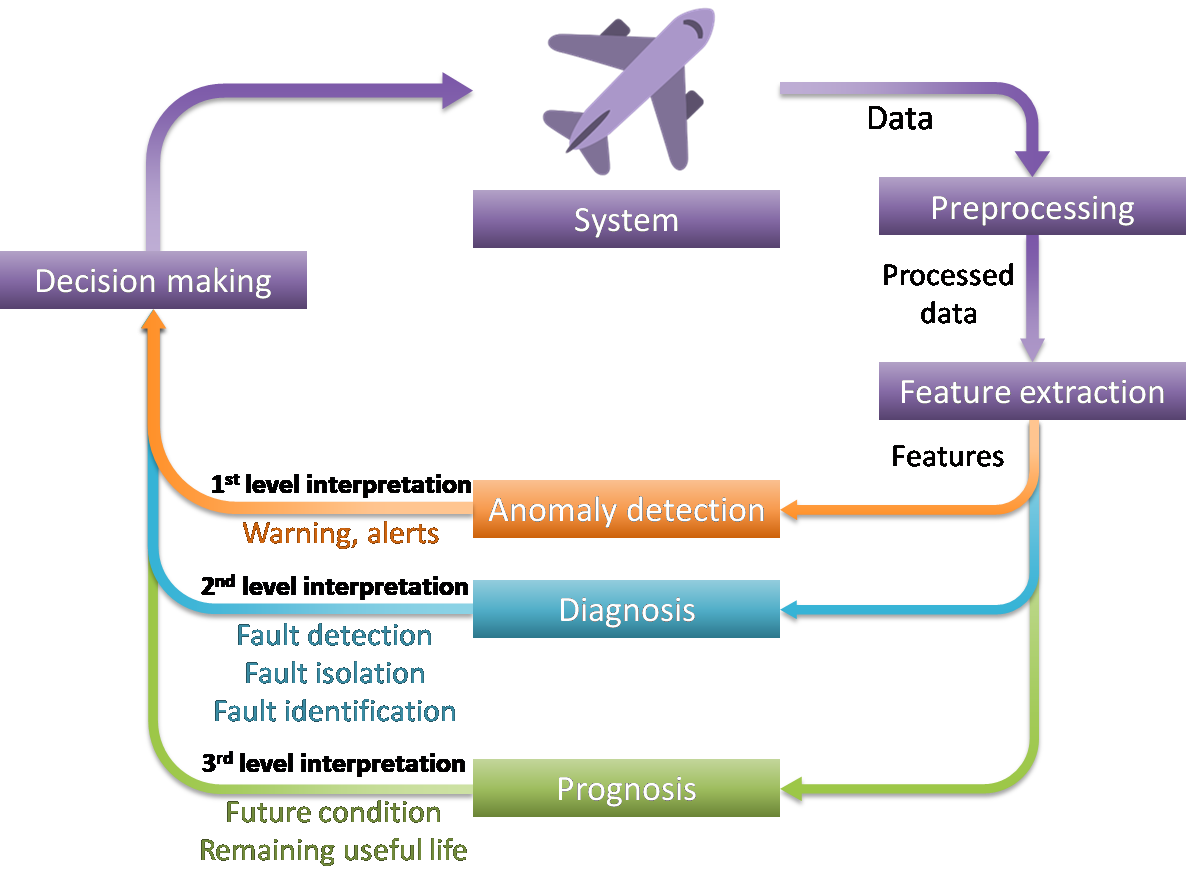

Prognostics and Health Management (PHM) is an engineering discipline to make optimal maintenance decisions by detecting anomalous behaviors, diagnosing current health conditions, and predicting the future health condition of engineered systems under actual operating conditions.

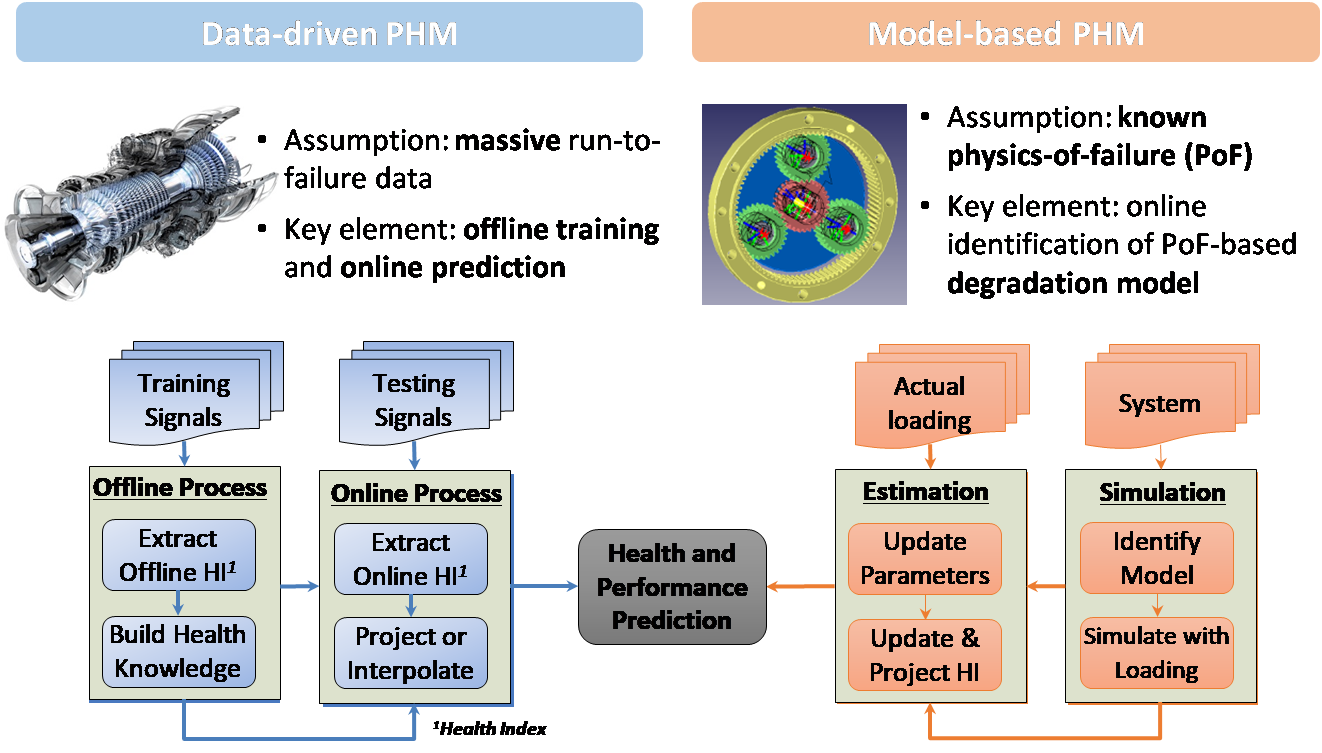

PHM includes two main approaches: data-driven and model-based. The data-driven approach extracts information from historical data of the performance of a product to capture trends of product health and predict the life using machine learning (or deep learning) techniques. The model-based approach uses knowledge of material properties, product geometry, life cycle loading and failure models to estimate the life of a product.

The design life of critical industrial systems such as power/petrochemical plants, manufacturing equipment and transportations can be up to 25 to 40 years. As the safety and reliability of engineered systems becomes important, diagnostic and prognostic methods have received more and more attentions. Key components in industrial machines such as motors, pumps, rotors, valves and power devices are actively studied.

H. Oh, et al., “Failure Mechanisms of Ball Bearings under Lightly Loaded, Non-Accelerated Usage Conditions,” Tribology International, Vol.81, pp. 291-299, January 2015.

B. Seo, et al., “Fault Detection Method for Solenoid Valves in Urban Railway Braking Systems using Temperature-Effect-Compensated Electric Signals,” Transactions of Korean Society of Mechanical Engineers, Vol.40, pp. 835-842, 2016.

H. Oh, et al., “Scalable and Unsupervised Feature Engineering using Vibration-Imaging and Deep Learning for Rotor System Diagnosis,” IEEE Transactions on Industrial Electronics, Vol. 65, pp. 3539-3549, March 2018.

H. Lee, et al., “Machine-Independent Permanent Magnet Motor Diagnostics with Artificial Fault Seeding and Kernel-SVM Fault Classifier,” ASME-International Design Engineering Technical Conferences & Computers and Information in Engineering Conference, August 2018.

Patent Application: H. Oh and H. Lee,"Method for Determining Fault of Motor," Republic of Korea,10-2018-0146023

C. Kim, et al., "Optimal Sensor Placement to Detect Ruptures in Pipeline System Subject to Uncertainty Using an Adam-mutated Genetic Algorithm," Structural Health Monitoring, Accepted

C. Kim and H. Oh,"Sensor Network Design Optimization Subject to Reduced Search Space with Explainable AI"

K. Lee and H. Oh,"Distance-based Anomaly Detection for Rotating Machine with Normal Data"